4000-year-old grain analyze with 21st century technology:Improving teff seeds quality with Size and Color Classification Technology using Vibe QM3i analyzer

- "The Grain Guru"

- Jul 30, 2025

- 3 min read

Introduction

Maskal Teff, a leading producer of teff, has been dedicated to providing high-quality, non-GMO, gluten-free teff to the global market for over 35 years. As demand for this nutrient-rich ancient grain grows, ensuring consistent quality becomes increasingly vital due to T

eff's extremely small seed size (similar to poppy seeds). Traditional classification methods are labor-intensive, time-consuming, and susceptible to human error.

To overcome these challenges, Maskal Teff collaborated with Vibe Imaging Analytics, an innovator in advanced imaging technology, to develop a specialized classification system tailored to Teff's unique characteristics. This partnership has resulted in an innovative solution that enhances quality control, accelerates processing, and improves accuracy and repeatability in Teff classification.

The Role of Advanced Imaging in Teff Classification

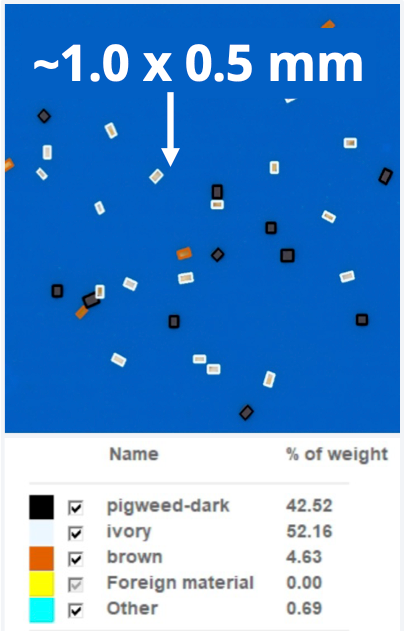

Vibe Imaging Analytics introduced the QM3i Grain Analyzer, an automated imaging system that classifies teff grains based on size, color, and purity. Key benefits of this technology include:

● Efficiency in a Labor-Intensive Process: Traditional teff classification requires meticulous manual inspection due to the grain's minute size. The automated system significantly reduces labor demands while increasing throughput.

● Size Classification: High-resolution imaging measures individual grains, ensuring consistency for milling and food applications.

● Color Identification: Automated systems identify and classify ivory and brown varieties of teff, detecting discoloration and impurities for accurate reporting.

● Purity Enhancement: Foreign particles like stones and chaff are identified, improving overall grain quality.

By automating these traditionally manual processes, the system reduces human error, enhances efficiency, and provides quantifiable, objective results for quality assurance.

Industry Impact

● Increased Speed and Accuracy: The automated classification system enables to assessment of large quantities of teff grains in a fraction of the time required by manual inspection, ensuring a faster and more reliable quality control process.

● Improved Product Consistency: Objective classification ensures that every batch meets stringent quality standards, reinforcing Maskal Teff's reputation as a trusted supplier.

● Economic and Sustainability Benefits: Early identification of quality issues optimizes resource use, reduces waste, and enhances operational efficiency, supporting a more sustainable supply chain.

Advancing the Future of Teff Processing

Integrating imaging technology with agronomic data allows Maskal Teff to link grain quality with factors such as soil conditions and harvesting methods. This data-driven approach enables farmers to refine their practices, leading to long-term improvements in teff production.

The QM3i also provides valuable insights for selecting high-quality seeds for future cultivation.

By identifying seeds with the best characteristics—such as optimal size, uniformity, and absence of defects—the system contributes to improved crop quality and yield over time. This feedback loop between classification and agronomic decisions empowers farmers to make informed choices that enhance production efficiency and sustainability.

Additionally, the QM3i plays a crucial role in reducing grain loss by accurately identifying defects and impurities, ensuring only high-quality grains move forward in processing. This increased efficiency translates into better resource utilization and lower overall waste, making teff production more sustainable and economically viable.

Conclusion

The collaboration between Maskal Teff and Vibe Imaging Analytics marks a significant advancement in the teff industry. By implementing advanced imaging classification, this partnership enhances efficiency, consistency, and sustainability in teff processing. The automated system not only expedites classification but also increases accuracy and repeatability, addressing one of the industry's most pressing challenges. As the industry evolves, Maskal Teff and Vibe Imaging Analytics continue to lead the way, setting new standards for innovation and excellence in grain quality management.

For more information about MASKAL TEFF, visit their website: teffco.com

Please contact us if you are interested in analyzing small seeds

Comments