The Science of Consistency: Applying 1000 Kernel Weight (TKW) to Modern Food Processing

- "The Grain Guru"

- Mar 27, 2025

- 2 min read

Updated: Dec 22, 2025

1. The Foundation: What is TKW?

Before understanding its potential in food processing, we must establish the standard used in agriculture. 1000 Kernel Weight (TKW) is an industry benchmark codified under ISO 520. It is a precise method of quality assurance that involves counting and weighing 1,000 clean kernels to calculate their average mass.

In the seed industry, this metric is non-negotiable. Jeremy Boychyn, MSc. P.Ag., Agronomy Research Extension Specialist at Alberta Wheat and Barley Commissions, notes its critical role in yield stability:

"The seed lot TKW is a key element for determining seeding rate calculations. When growing a wheat or barley crop, targeting specific seeding rates and plant stands increases the crop's yield potential as well as yield stability."

2. The Innovation: From Field to Factory

Traditionally, TKW was limited to the field. However, Vibe Imaging Analytics has methodically adapted this agronomic standard for the manufacturing floor.

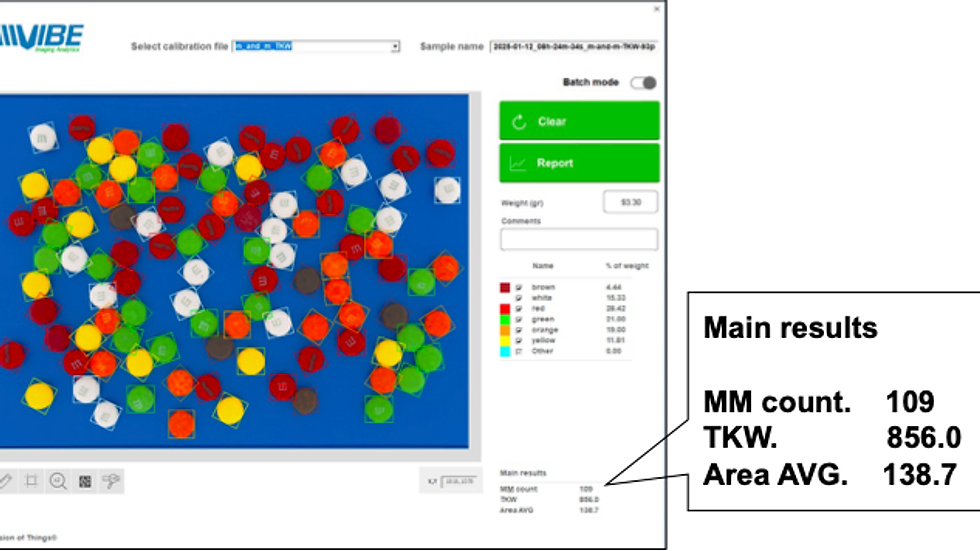

We recognized that the same metrics used to ensure seed yield could be used to optimize packaged foods—including breakfast cereals, pasta, snacks, and confectionery. By integrating TKW measurements with the Vibe QM3i Digital Analyzer, we don't just measure weight; we correlate it with color, size, shape, and surface properties.

This creates a multi-dimensional picture of product quality that simple weighing cannot achieve.

3. The Methodology: How TKW Optimizes Production

Implementing TKW analysis allows manufacturers to transition from reactive quality checks to proactive process control. By establishing specific minimum and maximum TKW ranges during product development, you create a rigid framework for consistency.

Here is how this methodology impacts three core areas of production:

Regulatory Compliance:Consistent kernel/piece weight ensures that nutritional labeling remains accurate regarding calorie and nutrient density per serving.

Operational Efficiency:Accurate TKW data allows for precise package filling. This eliminates the "giveaway" of product (overfilling) while preventing the regulatory risks of underfilling, directly impacting the bottom line.

Consumer Experience:Uniform size and weight result in consistent cooking times (for pasta) and mouthfeel (for snacks), driving higher customer satisfaction and brand loyalty.

4. Strategic Advantage: Adapting to Market Needs

The market is not static; consumers increasingly equate consistency with premium quality.

Using TKW as a key performance indicator (KPI) allows manufacturers to identify trends in their production line over time. If the TKW begins to drift, it is an early warning sign that the process or recipe needs adjustment. This data-driven approach allows producers to adapt to changing market demands without sacrificing the integrity of their product.

Conclusion: Data-Driven Quality Control

Enhancing food processing requires more than intuition; it requires the right data.

Vibe Imaging Analytics provides the expertise and technology to take TKW from a seed concept to a processing solution. By standardizing your 1000 Kernel Weight, you ensure that your operation is efficient, compliant, and ready for the future.

Contact Vibe Imaging Analytics today to integrate methodical quality control into your production line. info@vibeia.com

Comments